- Sorry, this product cannot be purchased.

AUTOMATICALLY TESTING SYSTEM FOR GLOVES, SHOES AND BOOTS UPG-40-6

netto

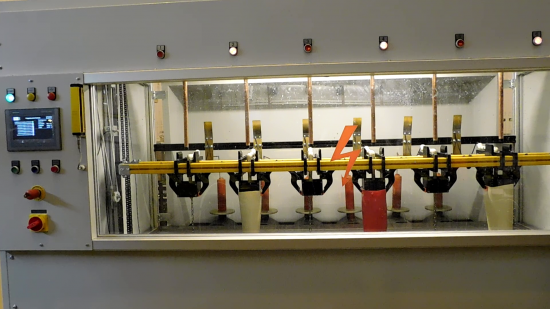

UPG-40-6 – automatic testing system for performing dielectric testing of personal protective equipment is modern device for testing the electric insulation of protective gloves, shoes and boots, incl. firemen’s footwear.

Testing of personal protective equipment:

- Gloves – class 00, 0, 1, 2, 3, and 4

- Boots – class 0, 1, 2, 3, and 4

- Sleeves – class 0, 1, 2, 3, and 4

Description

UPG-40-6 – automatic testing system for performing dielectric testing of personal protective equipment is modern device for testing the electric insulation of protective gloves, shoes and boots, incl. firemen’s footwear.

Testing of personal protective equipment:

- Gloves – class 00, 0, 1, 2, 3, and 4

- Boots – class 0, 1, 2, 3, and 4

- Sleeves – class 0, 1, 2, 3, and 4

- Simultaneous testing of 6 gloves

- Safe design

- Measurement, adjustment, control and protection systems

- Automatic measurement process

- Automatic hydraulic system

- Clear presentation of parameters

- Intuitive and ergonomic operation

- Compliance with harmonized standards EN 60903 and EN 50321

- Colour touch panel

- User-friendly interface

- Data archiving

- Ready-made programs for different classes of equipment, in compliance with the standards or own parameters

- Innovative solutions of test circuits – addressing of voltage fluctuations and stop of testing upon breakdown of any.

- Possibility to control of the outside transformer

- Manufacturing process parameters comply with Quality Management System acc. to PN-EN ISO 9001:2009.

TECHNICAL DATA

- Power – single-phase AC supply voltage, – 230V (120V 60Hz to order).

- Device parameters at AC high voltage sources:

- maximum operating voltage (RMS), – 40kV;

- maximum operating current (RMS), – 25mA.

- Power consumption, – max. 6,5 kVA.

- Reduced output voltage and current measurement error, %, – max. 3.

- Built-in timer.

- Weight: 540kg

- The volume of water: 285L

- Overall dimensions: 2550x1200x1940(H) mm

Błąd w tekście? Zaznacz, naciśnij Ctrl+Enter i wyślij nam zgłoszenie.

If you have found a spelling error, please, notify us by selecting that text and pressing Ctrl+Enter.

Characteristics

A stand for simultaneous testing – according to the type of measuring tank – 6 gloves, electrical insulating protective gloves, shoes and boots.

It consists of a cabinet provided with a measuring tank and a control cabinet with high voltage transformers, a control

autotransformer with a drive, control systems and protections. Due to a system of interlocks, protections and an automatic earthing switch, the system is safe to the operators and requires no demarcated test field.

Each measuring circuit is supplied from its own 40 kV 25mA high voltage test transformer. A test takes place

simultaneously on all the circuits. The system automatics allow filling the items under testing with water up to the required level and its immersion in the measuring tank.

The operation of the device is controlled by a microprocessor controller with a LCD touch screen. The parameters

for the item under testing is achieved by selecting the item from a scroll menu (by selecting the class and length of a glove or by programming one’s own parameters).